Tim

TECHNICAL INFORMATION / INTEGRATION MANAGER

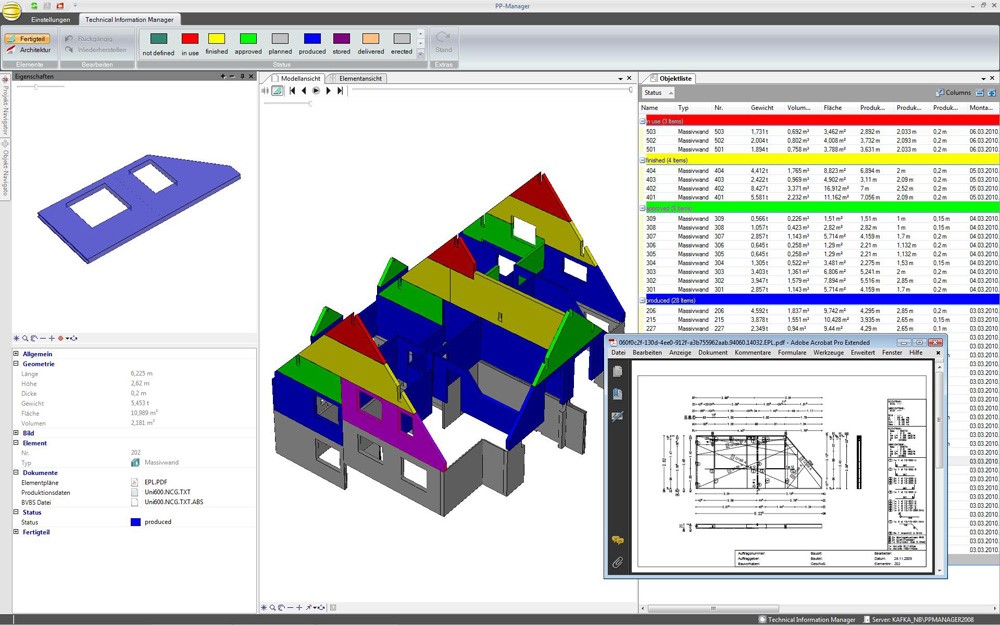

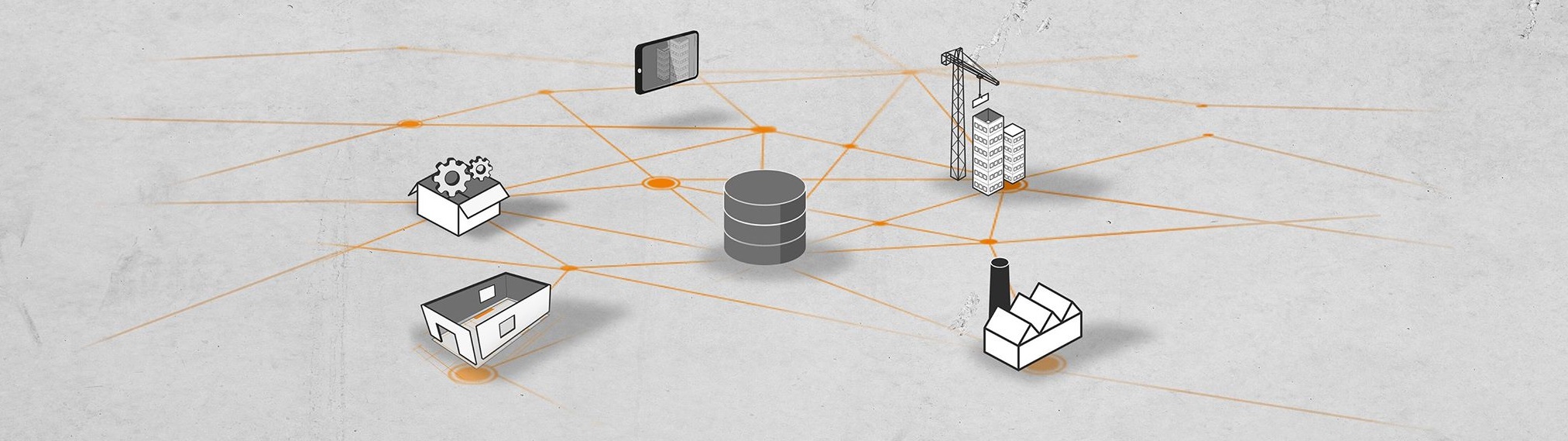

Techniczny INFORMACYJNY / INTEGRACYJNY Manager (Tim) jest platformą dla planowania 3D, pozwalającą zoptymalizować procesy związane z produkcją, logistyką, montażem i uzyskać dostosowane do potrzeb użytkownika graficzne raporty. Dzięki temu, że praca w Tim jest oparta na modelu 3D, proces zarządzania procesami jest jasny i przebiega intuicyjnie.

NAJWAŻNIEJSZE MOŻLIWOŚCI

INTEROPERACYJNOŚĆ

Integracja między systemami CAD, ERP, CAM i rozszerzeniami-modułami programu Tim pozwala uzyskać dużą efektywność w procesie produkcyjnym, transporcie i montażu. Dzięki modelowi projektu 3D, niezbędna informacja o każdym elemencie może być dostępna po jednym kliknięciu na element. Program Tim umożliwia wizualizację i monitorowanie całego procesu produkcyjnego.

Rozliczenia w systemie ERP odbywają się przez interfejsy:

- Formaty danych KST, ADS, ADS-XML, PXML, IFC

- Kontrolowany proces transferu danych umożliwiający eksport wysyłanie do systemu ERP plików i/lub treści w różnych formatach (np. prognozy zapotrzebowania materiałowego, przekaz na produkcję, fakturowanie)

Generowanie danych produkcyjnych może być wykonane przez interfejsy:

- IFC4 precast

- PXML lub interfejs Unitechnik CAD-CAM zawierający rysunki elementów

- Indywidualnie konfigurowany zgodnie z systemami docelowymi

- O dowolnej zawartości, nazwy pliku i katalogu wyjściowego

- Dla systemu ERP lub bezpośrednio na produkcje.

ZARZĄDZANIE PROCESEM PRODUKCJI

Oprogramowanie Tim pozwała zwizualizować proces produkcji i kontrolować aktualny stan każdego elementu, a tym samym w prosty sposób informuje o przygotowaniu do pracy, produkcji, sprzedaży i postępie procesu w projekcie budowlanym.

System do zarządzania stanami oferuje opcję precyzyjnego odwzorowania spersonalizowanego procesu roboczego dla elementów prefabrykowanych.

PRZYGOTOWANIE PROCESU PRODUKCYJNEGO

Moduł Collaboration Manager pozwala, po wybraniu projektu lub jego części w strukturze budynku projektu, szczegółowo przeglądać model budynku 3D i pobierać informacje o każdej prefabrykowanej części, częściach instalacyjnych aż po zbrojenie i dokumentację dotyczącą tych elementów.

Istnieje możliwość przydzielenia terminów realizacji dla każdej produkowanej części i automatycznie uzyskać harmonogram procesu produkcji.

Zintegrowane funkcje komunikacji pozwalają na wymianę informacją na temat tych elementów, która może być przedstawiona w sposób dostosowany do wymagań inwestora i innych uczestników procesu projektowania.

System do zarządzania stanami oferuje opcję precyzyjnego odwzorowania spersonalizowanego procesu roboczego dla elementów prefabrykowanych.

PROCES PRODUKCJI

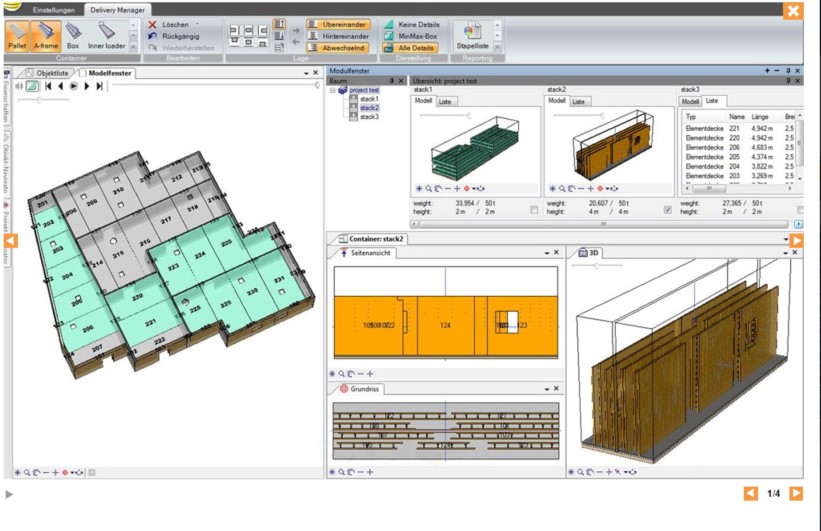

Moduł Production Manager umożliwia optymalne planowanie i umieszczenie elementów prefabrykacji na liniach produkcyjnych i paletach. Ponadto, moduł Production Manager pozwala skonfigurować linie produkcyjne.

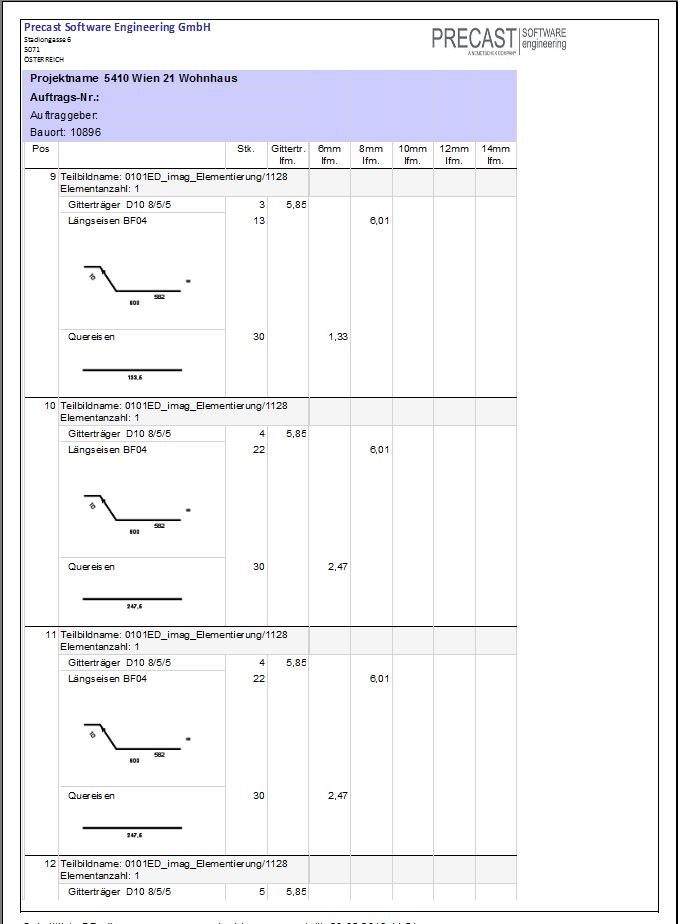

Dane, plany i listy mogą być przygotowane do produkcji, a następnie mogą zostać utworzone dla nich raporty. Niezależnie od tego, czy jest to UNI, PXML, ADS (BVBS) czy IFC, Tim generuje te raporty zgodnie z Twoimi indywidualnymi wymaganiami. Moduł Report Manager pozwala na generowanie plików produkcyjnych oraz zestawień zbiorczych, na przykład

Proces może być zautomatyzowany lub zintegrowany ze złożonym procesem roboczym.

Dodatkowo, istnieje możliwość wygenerowania etykiet, które można zsynchronizować z odpowiednią aplikacją mTim dla urządzeń mobilnych. Moduł mTim pozwala monitorować status elementów, zmieniając go wszystkie dokonane zmiany są natychmiastowo widoczne dla każdego podłączonego użytkownika Tim.